Waffle Pods

Home >> Construction >> Waffle Pods

Construction

Waffle Pods

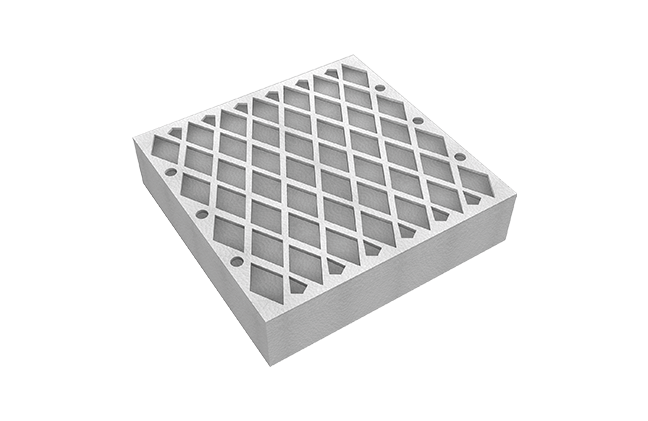

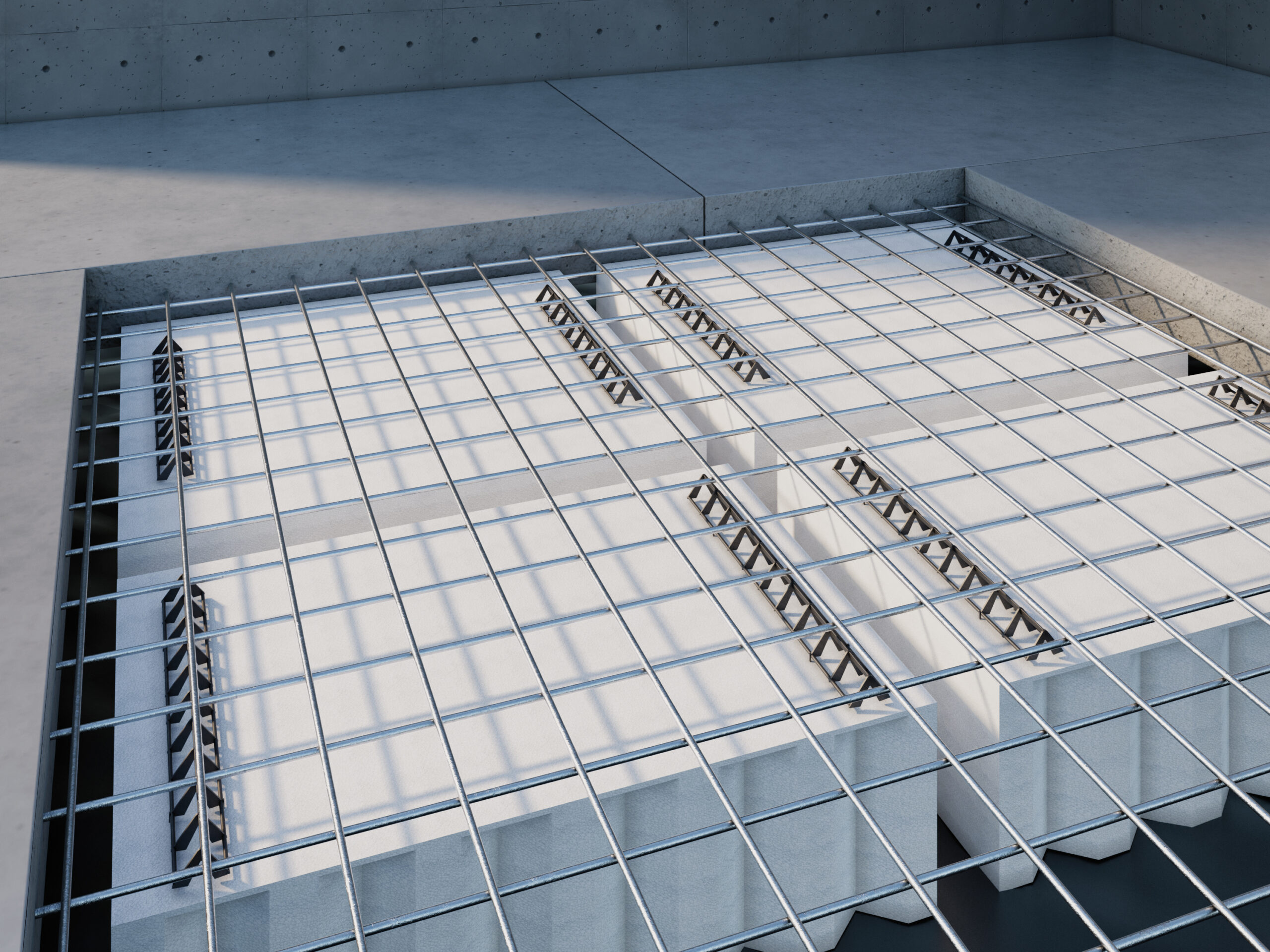

Waffle Pods, crafted from expanded polystyrene (EPS), have transformed domestic housing slab construction, making it safer, faster, and more cost-effective. This shift to EPS Pods from traditional concrete methods enhances slab strength and engineering while reducing the labor-intensive aspects of construction.

Their resistance to water streamlines construction timelines by negating weather-related delays and the hazards of trench cave-ins, ensuring consistent quality and scheduling. Additionally, the thermal insulation aspect of EPS Pods, offering up to an R 1.0 thermal resistance, lowers home energy usage. The adoption of EPS Pods across numerous homes significantly curtails greenhouse gas emissions, highlighting their positive environmental impact.

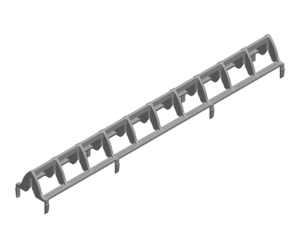

Waffle Pod Sizes

Waffle pods are available in these sizes:

- 1090 x 1090 x 150mm (Standard size in Queensland): Can be used in shower or garage set-downs, ideal for situations that require step down or height variations across the slab.

- 1090 x 1090 x 175mm (Standard size in Queensland; Made to order in Tasmania): Can be used in shower or garage set-downs, ideal for situations that require step down or height variations across the slab.

- 1090 x 1090 x 225mm (Standard Size): Best for moderately reactive clay or silt sites which can experience moderate movement from moisture change.

- 1090 x 1090 x 300mm (Standard Size): Can be used in highly reactive clay sites, which can experience high ground movement from moisture change.

- 1090 x 1090 x 375mm (Standard size in Queensland; Made to order in Tasmania): Recommended for use in extremely reactive sites that experience substantial ground movement from moisture change.

For other sizes, please ask our sales team.

EPSA Pod Stewardship

Polyfoam, as an esteemed member of Expanded Polystyrene Australia (EPSA), is committed to upholding the highest standards in the industry, particularly through our adherence to the EPSA Pod Stewardship Code of Conduct. This important code outlines guidelines for the responsible handling of EPS waffle pods, focusing on:

Safe Storage and Transportation

Ensuring EPS waffle pods are securely tied down during transport and storage to prevent accidents and environmental litter.

Proper Disposal of Contaminated Pods

Guidelines for the disposal of pods that have been contaminated by concrete, metal, or other substances, to ensure they are handled responsibly.

Recycling of Clean Scrap Pods

Encouraging the recycling of clean EPS pod scraps to promote sustainability and reduce waste.

Preventing Wind Dispersal

Implementing measures to prevent EPS pods from blowing away in windy conditions, safeguarding against environmental pollution.

Download a copy of the EPSA Pod Code of Practice below:

Waffle Pod FAQs

What type of soil is best suited to waffle pod slabs?

Waffle pod slabs are versatile and perform exceptionally well on non-reactive sites, slightly reactive clay sites, and some moderately reactive clay sites. However, they are not recommended for highly reactive clay sites (Class H1 and Class H2), ensuring optimal performance in suitable conditions.

What are the advantages of using waffle pod slabs?

- Cost-Effectiveness: Waffle pod slabs are more affordable due to simpler, faster preparation and reduced labor costs. They require less concrete and steel, making the construction process more economical.

- Simplified Construction Process: Their design simplifies the construction process with interconnecting components and less concrete use, saving time and reducing the need for heavy machinery.

- Strong Structural Stability: Offering enhanced stiffness and resistance to cracking, waffle pod slabs ensure long-lasting, safe structures with superior seismic strength.

- Improves Safety: With two-directional reinforcement, these slabs excel in vibration control, making them ideal for public buildings with heavy traffic, enhancing overall safety.

- Eases Installation of Construction Services: The design facilitates the easy installation of plumbing, electrical wiring, and other systems, saving time and effort.

- Environmentally Friendly: By using precise quantities of concrete and minimising soil disturbance, waffle pod slabs reduce waste and environmental impact, appealing to eco-conscious clients.

How do waffle pod slabs contribute to environmental sustainability?

Waffle pod slabs reduce waste and the environmental footprint by utilising specific amounts of concrete, eliminating the need for extensive trenching and soil excavation. This minimal disturbance to the soil and the avoidance of excess material makes them a sustainable choice for modern construction projects. You can find out more about expanded polystyrene (EPS) and its sustainability credentials here

Can waffle pod slabs be used for commercial buildings?

Yes, waffle pod slabs are particularly suited for commercial buildings due to their high load-carrying capacity, effective vibration control, and enhanced safety features. Their structural stability and efficiency in handling crowd-induced vibrations make them a reliable choice for buildings with high traffic.

Do waffle pod slabs save time in construction?

Absolutely. The interlocking design and lightweight nature of waffle pod slabs streamline the construction process, from site setup to the actual building phase. This efficiency results in significant time savings and a reduction in construction-related expenses, such as labour and equipment hire.

Are there any limitations to using waffle pod slabs?

While waffle pod slabs offer numerous benefits, their optimal use is subject to soil type suitability. They are not ideal for highly reactive clay sites (Class H1 and Class H2), highlighting the importance of site assessment before choosing this construction method.